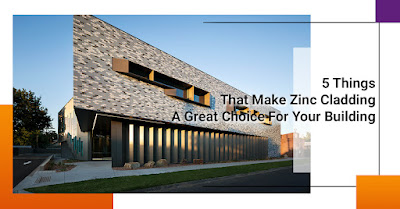

5 Things That Make Zinc Cladding A Great Choice For Your Building

Most commercial and public buildings and an increasing number of residential buildings use zinc in their design, whether for a roof surface, a building façade, or accessories such as trimming, flashings, or rainwater systems. Unlike other metals, zinc offers water tightness & aesthetics that exceed other materials such as roof shingles, vinyl siding or wood trim.

Here are some of the factors that make zinc facades a fantastic option for any building

Corrosion-Resistance

Once the zinc cladding is exposed to water, oxygen, and carbon dioxide, a chemical reaction creates a zinc hydroxycarbonate protective patina. The patina preserves the metal and prevents corrosion, making sure the cladding can endure many years. Some minor defects, such as scratches or bruises, may quickly develop a new patina, covering the exposed metal.

Calmer than Tin / Aluminium

Panels composed of Tin / Aluminium or other metals are less stiff than comparable panels. If struck by rains, hail, or other things, panels constructed from zinc would be considerably quieter than other materials, especially if coupled with the appropriate insulation in the building's structure. It makes the interior more peaceful and less loud for commercial or industrial buildings and makes it much more convenient for residential structures.

Relatively Affordable

The zinc cladding is exceptionally affordable compared to copper and stainless steel while maintaining the hardness and strength typical to most metal wall panels. It enables you to fulfil your materials' tight budget requirements and still have a solid and durable cladding that will endure for many decades.

Durable

Compared to other materials, such as steel, zinc cladding is more durable and will not corrode rapidly, resulting in premature failure. Zinc-cladding panels may readily survive for more than 70 years in urban settings, and they can easily last for more than 100 years in rural locations, depending on the conditions. In contrast to other materials, zinc cladding needs minimal care due to a natural chemical reaction that produces a patina that preserves the cladding surface while also removing any scratches or other minor flaws.

Zinc wall cladding is composed of natural elements that may be readily recycled after they have served their purpose. A house's carbon footprint is reduced as a result, which helps to preserve the environment. Furthermore, many zinc-cladding panels include up to 22 percent recycled content, which helps to decrease the amount of waste transported to landfills and the number of resources needed to extract new materials.

Zinc cladding is available in several textures and colours, each of which may lend a distinct appearance to your project. It can also be shaped in a variety of ways to accommodate even the most unusual architectural design. Zinc may be used to absorb light and, depending on how it is applied to the surface, can create various exciting colours and forms. Buildings with zinc cladding panels placed will have distinctive designs that will set them apart from their neighbours and make them stand out in a crowd.

It works well with various types of materials.

In addition to wood, stone, cement, glass, and concrete, zinc cladding may be used to highlight almost any other material. Combining these materials allows for the creation of an infinite number of one-of-a-kind patterns. This metal is also chemically compatible with various other metals, including brass, galvanized stainless steel, and other alloys of stainless steel. However, this should not be used in conjunction with uncoated steel or copper to prevent corrosion.

Because of its numerous advantageous characteristics, zinc cladding may be an excellent complement to virtually any project. Depending on the kind of cladding used, it may be installed fast and use several mounting techniques and it can endure for decades with little to no care. It may be used in nearly any architectural style, and it is very affordable compared to other metal panels.

Comments

Post a Comment